PhCNC is software specifically designed for PCB (Printed Circuit Board) prototyping, using the Accurate A3xx/A4xx/A5xx/A6xx/A7xx desktop CNC machines. It now includes several common machining functions. Our main goal was to create high quality software that is both extremely accurate and user friendly, with a very clear and simple to use interface utilizing pop-up menus, function buttons and high quality graphics. The Selections and calculations for standard operations are automatic, but the operations can be accessed by the user if needed. You can explore the PhCNC functionality through our demo (available at the “Software Demo” page). Please note that some of the software capabilities are missing in the demo version, nevertheless, it is completely functional, since it simulates the presence of the A350. We welcome you to try it out today without any obligations!

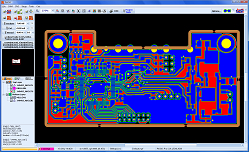

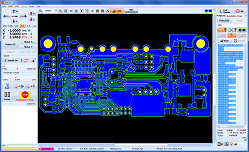

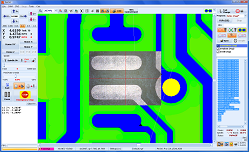

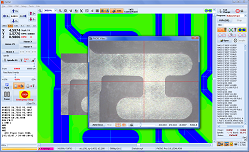

PhCNC has two modes of operation - the CAM mode and the CNC mode. At start up, PhCNC enters the CAM mode, where you can open your files and edit the final layout of your prototype. Here, you can also specify the tools, which will be used when the prototype PCB is being produced by the Accurate A3xx/A4xx/A5xx/A6xx/A7xx. In the CNC Mode, the user can execute the programs that have been generated by PhCNC to control the Accurate A3xx/A4xx/A5xx/A6xx/A7xx. Note that you can switch between the two modes at any time. If you have our new video camera/microscope you will be able to measure and inspect your project. Here is a screenshot of each of them:

| CAM mode | CNC mode | |

|

|

|

| CNC Video mode #1 | CNC Video mode #2 | |

|

|

Below are listed

the operations you can perform in each mode (PhCNC Pro is included in the price of all Accurate CNC machines in production). You can consult the

PhCNC User's Manual for a complete description of all the features

included in this software.

| File import | All models | Gerber RS-274X files; Excellon Drill and Definition files; AutoCAD DXF 2D files; CAM350 files |

| PhCNC project files | All models | Load / save / import PhCNC project files (PHJ) in case of repeated projects machining |

| Object manipulations | All models | Copy/ Delete/ Select/ Deselect/ Move/ Rotate/ Group/ Ungroup of objects and groups |

| Undo / Redo | All models | Undo and redo for all object operations |

| Insulation | All models | Insulation traces with up to 8 insulation tools |

| Rubout | All models | Assign rubout regions. Rubout with up to 16 tools (8 rubout tools + 8 insulation tools) |

| Remove spikes (IPD) | All models | Remove residual copper that remains as spikes (Insulation Problem Detector) |

| DRV & FI | All models | Automatic detection of design rules violation (DRV) & forced insulation (FI) option for the problematic areas |

| Breakout tabs | All models | Insertion of small interruptions of the cutout contour that allow the ready board to remain firmly attached to the main work piece |

| Vector text | All models | Allows insertion of simple vector text into the design or as a separate project |

| Holes and pads insertion | All models | Insertion of holes and pads |

| Panelization | All models | PCB panelization |

| Gerber Export | All models | Export gerber & drill files |

| All models | Print gerber files | |

| Contour selection | All models | Select inner / outer tool diameter compensation for all cutting operations |

| Visualization modes | All models | Various modes of visualization of the project layers |

| "Machining window" | All models | For machining of a pre-selected area of the project or processing of oversized projects along X axis |

| "Peck" mode | All models | "Peck" mode solution for all high aspect ratio machining (up to 10 mm depth) |

| Tools selection | All models | Selection of tools for insullation, rubout, drill, cutout and stencil |

| Switching CAM & CNC mode | All models | One click switching between CAM & CNC mode |

List of available operations in the CNC mode:

| Tool change | Model dependent | ▪ Automatic change and calibratinon of the tools without any operator's activity ▪ Manual change and automatic calibration of the tools |

| Insulation program | All models | Program for tracks and pads insulation |

| Rubout program | All models | Program for removing of excessive copper rubout for the selected regions |

| Drill program | All models | Program for dirilling and / or cutting of the project holes |

| Cutout program | All models | Program for cutout with breakout tabs (if inserted) |

| Stencil program | All models | Program for cutout of stencil |

| Batch program execution | ATC models | Executes all generated programs for the top or bottom layer |

| Fiducial registration | All models | For project positioning and matching of top and bottom layers |

| Quality control | Model dependent | ▪ Positioning and measurement with camera / microscope ▪ None (if no camera installed) |

| Machine control programs | All models | Industry standard G & M codes ASCII, PHJ job files |

| Periferal devices start/stop | All models | Spindle and vacuum start-stop (Program controlled, manual override available) |

| Feed rate control | All models | Program controlled, manual override available |

| Spindle speed control | All models | Program controlled, manual override available |

| Auto Fiducial Registration | All models | Fully Automatic Fiducial Registration; Assisted Fiducial Registration; Manual Fiducial Registration; |

Even though, the software is very powerful, it is designed to be incredibly easy to use, so once you are equipped with the Accurate A3xx/A4xx/A5xx/A6xx run by PhCNC your PCB prototype is just a few clicks away. Just load your PCB files, indicate the tools for insulation, rubout and cutout, and the Accurate A3xx/A4xx/A5xx/A6xx is ready to start.

PhCNC is not simply the software that drives our machines. It is the "backbone" of the entire system that controls and communicates with all system components.

• PhCNC360™ our CNC controller

• PhACdrive™ our AC/BLDC vector spindle drive

• PhSTdrive™ our all axes intelligent stepper drives.

Named above controllers are used in our current models and are designed and manufactured by our company. We are using 100% gold plated circuit boards and the best assembly shops in order to have the highest possible reliability available by the current technologies.

All controllers above are also in communication with PhCNC software and will receive a firmware updates (if needed) during the installation of a newer PhCNC revision. This approach make us also leaders in the innovations in the PCB prototyping and micro-machining business.

All new models listed currently on our web site are extremely accurate. The absolute accuracy is definitely 8 to 10 TIMES better than the competitors and they never published this parameter. It is logical to ask how we achieve this and how we are reaching this conclusion. The answer is short and prompt. Using high quality linear encoders we study the actual positioning that you can get from the highest quality screws and nuts. It is logical that the absolute positioning errors exist in all models on the market. What we did?

• for all standard models we start calibrating the screw/motor assemblies. We run them end to end in a 0.01 inch (0.25 mm) steps and compare the position with the reading from a temporary mounted high accuracy linear encoder. As a result we got a "map" of the screw inaccuracy that is recorded in the axis intelligent PhSTdrive and dynamically compensated during the actual positioning.

• for all high end models we have the linear encoders permanently mounted and full servo positioning feedback also allowed by the PhSTdrive capabilities.

• on top of this we have full thermal compensation for the screws, encoders and even the material under machining, allowing our systems to be the most accurate in the current market.

What is handling this complicated but very effective accuracy improvements. It is the PhCNC control software. This is the reason to call it the "backbone" of our systems.

News about latest revisions of PhCNC:

• PhCNC64 - 64bit version of PhCNC for x64 Windows (Vista/Win7/8/8.1).

PhCNC64 (64bit) is completely identical, functionally and visually with PhCNC (32bit). The main advantage is that it can address more than 4GB RAM (extremely good solution for handling large and complicated projects).

• Multithreading - Now PhCNC & PhCNC64 are capable of using parallel processing that allows significant improvement in processing of large and complicated projects.

Minimum system requirements for PhCNC (32-bit):

• OS: Windows XP/Vista/7/8/8.1/10 (x86/32-bit) or XP/Vista/7/8/8.1/10 (x64/64-bit)

• CPU: 2GHz (2+ logical cores for using Auto Fiducial Registration)

• RAM: 1GB

• Video: 1024x768

• 1 USB 2.0 port

Minimum system

requirements for PhCNC64 (64-bit):

• OS: Windows Vista/7/8/8.1/10/11 (x64/64-bit) *

• CPU: 2GHz (2+ logical cores for using Auto Fiducial Registration)

• RAM: 2GB

• Video: 1024x768

• 1 USB 2.0 port

* Windows XP 64-bit is not supported!

Other Recommended Links:

►

Our software versus others - Article, showing with table and pictures the results from performed tests with our software and the competitors' ones.

► Machines' review - Review of our machines' parameters and features

►

Dynamic selector of PCB prototyping system with prices► Machines' review - Review of our machines' parameters and features

+1 (260) 489-7600

+1 (260) 489-7600